Extending Production Control From Office to the Shop Floor

SICAM is a networked software that communicates between the machines and the office. We make full use of this ability to increase your productivity and simplify the production process.

- Networked Software

- Production Logging

- Define User Roles

Instantly share data between the office and your shop.

All your SICAM-enabled computers automatically store their information in a common database. As you work on parts and nests in the office, they are updated at the machine. As the machine works through its production, the production status is logged and can be checked in the office.

All this is done to simplify the process, so your production can be faster and more accurate.

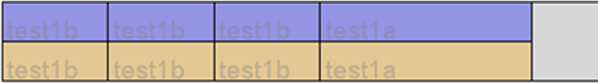

Automatic Beam and Plate Nesting

SICAM's automatic beam and plate nesting generates optimal results to reduce material usage as much as possible. Miter-cut beams are automatically detected & rotated to reduce drop. SICAM can mult WT beams, detecting optimal part size and automatically sorting them. The plate nesting has a wide array of features for nest generation.

Edit or Create Parts in the Built-In CAD Editing Package

Using a familiar oCAD-style interface, SICAM's part editor allows you to quickly creat or edit all your parts. Advanced toolpath controls enable complex coping as well as detailed daps.aF

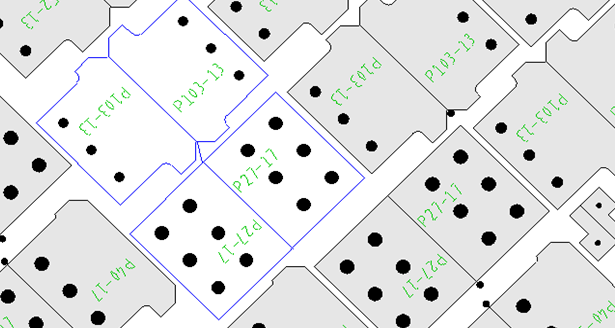

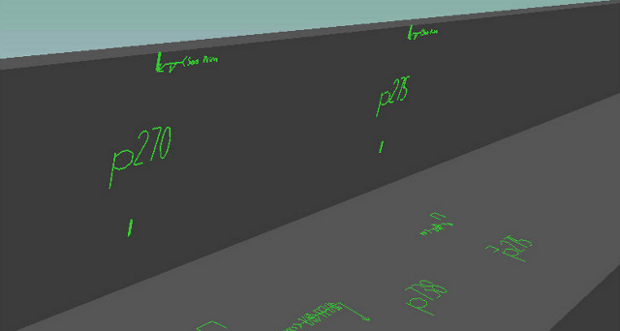

Prepare for the Future with Assembly Layout Marking

SICAM now works with SDS/2 and Tekla for loading assembly information directly from the model. We can use this information to generate layout marks and weld information directly on the surface of the parts.

SICAM gererates both the layout

marks and welding information based on the assembly data

from the detailing software.

SICAM gererates both the layout

marks and welding information based on the assembly data

from the detailing software.Integrate With Our Industry Software Partners

Improve our production process with SICAM's integration support for a variety of software partners. We work with production management softare and detailing softare to create a more effecient, accurate environment.

Production Status Feedback

SICAM works closely with FabTrol and Fabsuite production management software. Send your cut lists to SICAM ready for production at the machine. Get realtime status as parts are completed at the machine.

Online Software Support

Controlled Automation's software support staff can help you on the phone, over the internet and through email. We quickly resolve issues online, without the need for an expensive service visit. Office hours are 8:00 AM to 5:00 PM CST (-5 GMT)